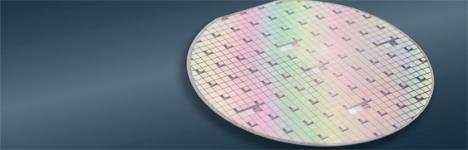

The Micronic system, based on the company's spatial light modulator (SLM), uses laser technology to generate photomask patterns of the same resolution as a considerably slower electron beam system. SLM is based on reflection of shortwavelength laser pulses on a matrix of micro mirrors, developed at the Fraunhofer Institute in Dresden.

Each mirror can be controlled individually, which means that each reflected laser beam can generate high-resolution patterns. At the moment a 32 x 8mm matrix of one million 16 x 16um mirrors is used to create high-resolution photomasks.

Initially, the SLM technology will be used to generate structures down to 130nm. However, according to Micronic, the technology can reach dimensions of less than 100nm in a couple of year's time.

Gittan Cedervall